Makerspaces and the MEC system

Makerspaces are becoming an important part of STEM education. A Makerspace can be more than just a space where students play with 3D printers. A Makerspace can be a place where students engage in real world problem solving. For that to happen we have to acknowledge the interdisciplinary nature of real world problems in the 21 st century, and provide students with the tools, skills and materials necessary to attack these problems.

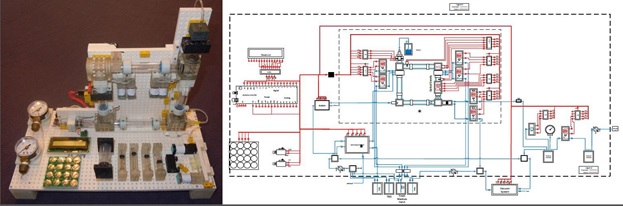

The Multifluidic Evolutionary Component (MEC) system [1-4] is uniquely qualified to address this problem. It is a multidisciplinary component set that was developed for biological and chemical instrument advancement. The components are structured in a way that allows them to be easily interconnected, even though they can have very different functions (fluidic, electronic, optical, and mechanical). MECs were developed to solve fluidic problems that can occur at multiple scales. Control and sensing is primarily through electrical and computer interfaces. The MEC system is backed by a software/microcontroller system that allows the user instrument control through a laptop or simple electronic interface. Users can design and build their own unique instruments or select from an ever-growing library of existing symbolic interdisciplinary instrument designs.

Real world problems engage students and can create a focus for a Makerspace. Solutions for real world problems like cancer, hunger, and climate change can all be developed using a MEC analytical bioreactor (shown below) as a starting platform. The bioreactor is component based and can take many forms. As students customize to a particular application they will be learning valuable engineering skills.

Fully engaged students have no limit to what they can accomplish. Often, in school, especially in disadvantaged areas, students may have no idea why they are learning higher-level math or science. This is why a project that uses real world problems is so helpful, because the student can see the reason for what they are doing. To accomplish these real-world goals, students will need to learn new skills, and reason drives them to accomplish this. Real world problems are so multidisciplinary that you can find areas that can engage almost any student. My interns are at the college level, and I work to match a students’ interests with the portion of the problem that will most engage them and require the skill building they desire. For high school this could be problematic in a regular classroom, because different students are learning different skill sets. For a summer program, this works exceptionally well because each student can achieve and learn in their area of interest. Students are free to learn and perform at whatever level they are capable of. The MEC system has the potential of accelerating what a student can accomplish and increasing their level of achievement, because it builds on a pre-existing engineering system.

Time is another key problem. A teacher’s curriculum is so defined that it leaves little time for creative problem solving. I was once told by a teacher who was attempting to integrate projects into his classroom that creative problem solving was not on his list of teaching requirements in the course, and therefore, little, if any, time could be allocated for it. I home schooled one of my children in math, and with the workbook I was given, I, too, had little time to teach creative problem solving. A change is needed. Summer and academic after school programs may be a place to start, with Makerspaces. By recognizing that real world problems are multidisciplinary, time could be spent across multiple classroom periods, such as math, physics, biology, computer science and English. This enriches each lesson, provides more time, and demonstrates how multiple subjects are interconnected. Cross-disciplinary teaching, although challenging for the teachers from a coordination standpoint, can be quite an enriching experience for the students. Having adequate time is one of the biggest challenges my interns face in solving problems, with all their other obligations as undergraduates at the University of California.

Teacher training: A Makerspace instructor’s primary focus should be to help students learn how to break down a problem and find the necessary resources to solve the problem themselves. A large percentage of the resources are cloud based, where a student may be going through a tutorial on how to use a specific piece of software or perform a process. My students (interns) at UC Riverside have learned software like Solidworks and Visio, printed circuit board design, glass etching, CNC machining, lathe machining, Python programming, Arduino programming, C++ programming, web design, YouTube video production, 3D printing, drilling, sawing, and many more skills. They learn about important biochemical processes like ELISA, and the physics of how a motor works. Each student does not learn everything, but they learn the skills that are needed to get their portion of the job done, hopefully in their area of interest. Since I deal in real-world problems, I’ve needed my students to work in all of these areas, yet it is important to note that I still do not know how to do a lot of what is listed, and I’ve been doing it for many years. To teach someone how to solve a problem, it is not necessary to have all the skills yourself. A student needs to be able to teach a student how to recognize what skills are needed, and how to teach themselves those skills. A teacher needs to be an expert in finding the necessary resources. Students will also require help in understanding what is possible with the resources that are available.

Experts: In my vision of a Makerspace, teachers would ask students to solve problems the teachers themselves do not know how to solve directly. This is a scary prospect for anyone. For a high school teacher, I would want them to have a network of partners in industry and universities. Even retired professionals and college students could aid teachers in helping their students solve problems. In my program I have a lot of students teaching each other, and I assume that model would hold with other Makerspaces. I believe it may be challenging to get physical support at the school, but I believe though phone, Skype, and email we can develop a powerful network. Industrial partners are not only experts in the skill sets, but also in the problem solving process. I have also found that retired professionals can be a powerful resource.

Practitioners: As schools work to solve real world problem, they need to be linked to practitioners; individuals who are the end users of the technology being developed. These practitioners include physicians (who may use students’ tools in the operating room), plant scientists (who may use students’ creations in the field), and industrial researchers (who may use student’s inventions in companies). Practitioners possess a full understanding of the problems to be solved. They also may have real world data or samples to assist in the development of solutions. Schools need to work together at all levels in solving these complex problems. Industry can provide both insight into their needs and core challenges, and assistance in training of students. Time, once again, is the limiting factor, so methods for making it beneficial for both parties is critical, as is minimizing needed interface time while maximizing productivity. Partnerships formed because of a specific grant can be weak and temporary. I look for relationships that are mutually beneficial, with or without external funding.

Materials: When a student is starting a project, one of the first things I have them determine is what Knowledge and Materials are needed. Over time, there is a lot of repetition regarding where materials are coming from. Students need to be provided links to where they can locate materials. As new projects evolve, this database should be able to organically grow from new sources that students find. The Makerspace should have a large assortment of raw materials, and the students need to be made aware of what raw material they have.

Equipment: We have to strive to provide access to students for the tools and equipment they need to achieve their goals. The basic tools should be in the Makerspace, but surrounding schools or businesses may have tools that could also be used. The starting equipment I suggest for a real-world problem-solving makerspace is a drill press, scroll saw, belt sander, small press, electrical multi-meter, soldering iron, and a 3D printer. 3D printers are fantastic, but personal experience has taught me that you get what you pay for. The vision is that one can make whatever one imagines, but 3D printers have many limitations associated with them. One is limited in both material selection, and by low tolerances. 3D printed materials can be toxic to organisms and require secondary machining operations. Thus, students should dream big but understand the limitations. Additional equipment could include a tabletop CNC machine, lathe, microscope with camera, laser scribe, and oven.

Website: Next, we need a resource Website that guides students and teachers to relevant videos, tutorials, material, experts, etc. This website is currently under development at http://evolutionarycomponents.org.

Tutorial: Because the Makerspace teacher cannot be an expert in all the interdisciplinary areas that a student may explore in solving problems, the web becomes a vital resource. The http://evolutionarycomponents.org website will help guide students to the appropriate tutorials. Many videos on YouTube and other tutorials have already been developed by others, but we are also developing our own tutorials that are tailored to teaching the information needed to solve problems using the MEC system. The web site and these more directed tutorials allow students to be more efficient with their time, allowing them to solve problems faster.

Student Projects: Seeing what other students have accomplished can be a good source of inspiration for students. If the projects are properly documented they can also be a good source of information for students. We need to strive to build on each other’s work instead of starting over with each student project. The MEC system can help facilitate this with its component based approach, and multidisciplinary schematics.

Results: The internet-based “Cloud” will inevitably change medical diagnostics, and instrument development, but today we sit well below what is possible. In fact, some say researchers are in a crisis due to our inability to duplicate much experimental research. This topic may be outside what is needed to be discussed on Makerspaces and student projects, but I believe that the sooner students can be made a real part of the solution, the more engaged and recognized their work will be. Students’ experimental results need to include precisely how these results were obtained. This includes the equipment used by the students and its setup and operation. Standards need to be developed which would allow computers to comb databases and automatically process this information. The MEC system has taken steps that will help with this effort. First, we have developed an interdisciplinary schematic for the MEC components that allows the user to fully define (and share) the hardware they use. Second, our MEC software can record not only data but also the hardware, software, and operations used to obtain that data and store this information on the “Cloud.” Third, the cost of instrumentation is a barrier to its ability to be duplicated. The MEC system lowers that barrier. Fourth, the MEC system can automate processes, remove human error, and allow for more repetition in testing.

Problems: The http://evolutionarycomponents.org website will include a database of real world problems that face us today and that could be addressed by a Makerspace. The site will provide links to other websites or research articles where the problem can be explored in more depth.

Experts: Whether it is a software program, or a biological process, students need to be linked to people who can help them understand how to use a tool or run a process. These experts can be local or across the world. They can come from industry or academia.

Materials and Equipment: The http://evolutionarycomponents.org website will include databases of materials and equipment available for student use. This includes both material and equipment inside the Makerspace and outside the Makerspace (in area businesses, colleges, universities, etc.).

Costs: A Makerspace should be filled with components available for student use, but this is only possible if the cost of these components is low. I have the philosophy of always trying to work from raw low-cost materials. Many of these components are made with 3D printers. Making components from raw materials takes time, but it keeps cost low and opens up the possibility for more replication of work from student to student or Makerspace to Makerspace. It also allows students to design, build, and understand instruments down to their basic components. The Makerspace filled with physical material is best, but a virtual library of components that can be readily fabricated with a 3D printer and assembled is a lower cost option that still opens up a world of possibilities for the student.

WebLab: The MEC system provides the ability to automate lab experimental processes. If you combine this capacity with a Web cam and a little bit of software, you will have what I call WebLab. A WebLab-based experiment can be controlled and viewed through the Web. These experiments could be built in cloud lab stations that, like docks for experiments on the Space Shuttle, can accommodate a variety of different WebLab-based experiments. Each dock has a set dimensional size and a set of utilities provided, including power, water, waste removal, and a Web cam. Additionally, we will have developed a cloud interface with data storage, control, and data visualization.

Technology Transfer: I believe that various types of cancer have been cured in research labs across the United States, but researchers still need to test and refine these existing methods. The MEC system offers the promise of being able to automate those existing methods, allowing the transfer and refinement of techniques that is needed for their rapid evolution into clinical solutions. This will continue to be a goal of the TEC Center.

Grant funding: My biggest problem is how slow instruments and reliable components progress. My instruments and components are being developed by undergrads, and their volunteer time is limited. Each student tries to maintain a five-hour commitment every week, but even that can be a challenge. Classes have to take priority, but if small amounts of funds are used to pay some interns, it does accelerate the program, since the interns become more reliable and consistent. There are also repetitive jobs that need to be done; jobs that a volunteer may hesitate to do but a paid intern has no problem with. Small amounts of funding used in this way also help pay students’ schooling. I was also wondering what a small amount of funding for students in high schools in disadvantaged areas would do. I would assume it would have the same positive effects. One reason a student may not be able to participate in a summer program is that they need to work to help the family. Here, I believe industry can also help. Since industry would receive workers with more refined skill sets tailored to their needs, they may be interested in helping with this type of program. Additionally, the real world problems that are being addressed may be directed partially by industry. Grant funding should be organized from the bottom up, so that the bulk of the funding goes to the work force at the bottom and the equipment and materials they need.

Legislation: Encrypted large cloud-based medical records of patients will be vital for the early detection of diseases. These medical records would contain a patient’s testing record, including blood tests, pap smears, MRI, etc., as well as the diagnoses of doctors and which drugs were prescribed. Software can then be written that anonymously uses this data from millions of people and looks for patterns, so a person with a similar problem can be diagnosed early. Thousands of lives today could be saved if this data was available. What I propose is that upon a person’s death this information is encrypted so the identity of the person is protected, but the data is made public. If a person wished their medical records not to be made public they could fill out a form and it would be kept sealed. For the majority of us we would not care, and with that data lives would be saved. Students could be engaged in developing software for looking at this data and searching for patterns. With my own medical records I’m already engaging students to develop software to look for patterns.

Thanks to the supporters of the TEC Center!

-

The Center for Bioengineering Research at the University of California, Riverside

Development of the MEC system was supported by Prof. Jerome Schultz and the Center for Bioengineering Research at the University of California, Riverside.

-

The National Science Foundation

Development of the MEC system was supported by the Instrument Development for Biological Research (IDBR) program of the National Science Foundation under award DBI-1353974.

-

Sophomore STEM Success Awards from the Office of Undergraduate Education at the University of California, Riverside

Three of our students— undergrads Raymond Iu (Bioengineering), Hayden Karich (Mechanical Engineering), and Manoel Tamraz (Bioengineering)—received the Sophomore STEM Success Award from the Office of Undergraduate Education at the University of California, Riverside.

-

Best Buy Foundation

Thank you to the Best Buy Foundation for supporting the TEC Center!