My Story and the TEC Center

by Douglas Hill

Since I was little I have always loved learning and creating, whether it’s building a robotic costume or writing a story. My higher education began with an electrical engineering B.S. degree from the University of California, Irvine in June 1979. My first job was with Texas Instruments where I was given the honor of being the only Junior Engineer listed as a “Key Contributor.” At Texas Instruments I began my electronic packaging career. My job was to shrink the size of a power supply by a factor of 10. I did this by redesigning the power supply’s magnetics and developing my own family of surface mount components. I still remember when we first turned on my miniature power inductor, which was smaller and more efficient than anything that had been made before, and even though the insulation melted off the load wires, my part stayed cool.

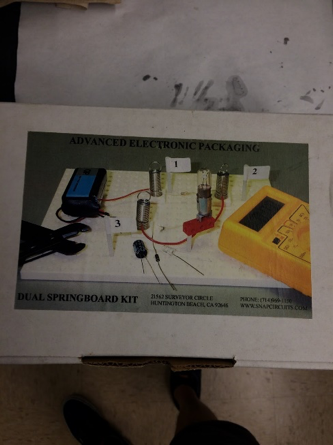

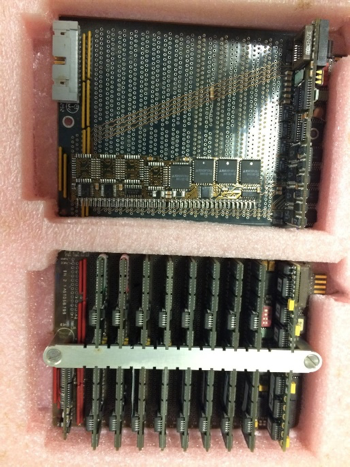

After a year, I left TI to start my own business in California, with a short break to sail an 18 foot catamaran from Trinidad to Florida. My system design house was known as Advanced Electronic Packaging Corporation. Its mission was to solve electronic packaging problems, which means fitting a lot of electronics into a small space. I planned on doing this through the use of surface mount components, which at the time where ceramic. Ceramic parts where expensive, so they were not in widespread use. But then Texas Instruments came out with the first plastic surface mount component, the 64K X1 DRAM. Being one of few houses that knew how to work with surface mount components, I landed a large contract with Alpha Micro, a computer manufacturer. My business helped lead the transition from “through hole” technology to surface mounted technology. In the end I designed for several of the worlds largest corporations, including IBM, Ford, Motorola, Northrop Grumman, AT&T, Gilbarco, the US Navy, Woods Hole Oceanographic Institute, and the NASA Jet Propulsion Laboratory. My business spanned over 15 years. I was one of the early inventors of memory sticks that can be seen in computers today. As surface mount components became more popular, my business transitioned from modules to systems like the memory system I developed for the US Navy. But even though I was able to be creative and solve my customers’ problems, I was not able to select the problems I solved. So I set out to choose a problem that I wanted to solve.

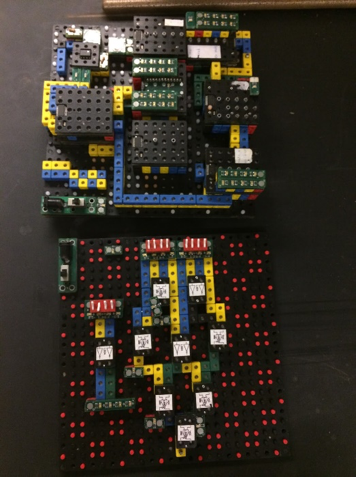

I chose to address the need for creative problem solving in the educational system. Building upon my experience in electronic packaging, it seemed only natural to build a set of building blocks for making electronic circuits. Students could use these blocks along with their most powerful tool—their imaginations—to solve problems and learn about electronics. I called these blocks Snap Circuits, I developed several Snap Circuit kits that I rented and sold to schools. I also ran summer programs using Snap Circuits. In one of the programs I led in Compton, I remember talking to one of the teachers about a young girl in my class who was obviously gifted. I was surprised to find out from the teachers that the girl had been kicked out of school, which was why she was in my program. This girl had “failed” traditional classes but excelled in problem solving using my Snap Circuits. I remember helping another student build a simple light tower, and as I walked away, I watched the student tear it down and rebuild it his own way. He was already talking ownership over his design. I also worked with college students, and in contrast to the high school students, the college students would ask, “where are the instructions?” The high school kids from Compton were used to being independent and solving their own problems; they succeeded where college students struggled.

I chose to address the need for creative problem solving in the educational system. Building upon my experience in electronic packaging, it seemed only natural to build a set of building blocks for making electronic circuits. Students could use these blocks along with their most powerful tool—their imaginations—to solve problems and learn about electronics. I called these blocks Snap Circuits, I developed several Snap Circuit kits that I rented and sold to schools. I also ran summer programs using Snap Circuits. In one of the programs I led in Compton, I remember talking to one of the teachers about a young girl in my class who was obviously gifted. I was surprised to find out from the teachers that the girl had been kicked out of school, which was why she was in my program. This girl had “failed” traditional classes but excelled in problem solving using my Snap Circuits. I remember helping another student build a simple light tower, and as I walked away, I watched the student tear it down and rebuild it his own way. He was already talking ownership over his design. I also worked with college students, and in contrast to the high school students, the college students would ask, “where are the instructions?” The high school kids from Compton were used to being independent and solving their own problems; they succeeded where college students struggled.

From my experiences using Snap Circuits in classrooms, I developed my philosophy on why kids from disadvantaged communities often struggle in school. It’s the vision the kids have. Kids without vision don’t see themselves going to college, so the problems they are asked to solve in school seem like a waste of time. But if a student has vision, the problems they solve in class may still may look like a waste of time, but the student realizes that this is what is required for them to get to where they want to be (college and a good job). But if you can challenge students to solve real-world problems, they’ll no longer feel like they are wasting their time. They’ll work on solving the problems because the problems are important and touch their lives. And in the process, they will learn and reach the top of their potential. Providing these opportunities to students is a major focus of my work.

From my experiences using Snap Circuits in classrooms, I developed my philosophy on why kids from disadvantaged communities often struggle in school. It’s the vision the kids have. Kids without vision don’t see themselves going to college, so the problems they are asked to solve in school seem like a waste of time. But if a student has vision, the problems they solve in class may still may look like a waste of time, but the student realizes that this is what is required for them to get to where they want to be (college and a good job). But if you can challenge students to solve real-world problems, they’ll no longer feel like they are wasting their time. They’ll work on solving the problems because the problems are important and touch their lives. And in the process, they will learn and reach the top of their potential. Providing these opportunities to students is a major focus of my work.

In my business, I was used to world where I provided engineers with solutions, and in return they provided me contracts. The educational community was very different, with low budgets and strict guidelines, and teachers often didn’t have the time or money required for creative problem solving. I reached my goal of bringing creative problem solving into the classroom, but lost my business focus in the process, which ultimately caused me to close my business. But in one of my last business projects, the US Navy contacted me needing a very high reliability system. It was to be launched remotely under the ocean. I came up with a method for predicting a failure in the system before the failure actually occurred. In this technique, which I called gray scaling, the system tests and records system parameters every time the system is turned on. Over time the system learned what was normal, and if the system saw a shift out of normal behavior, it would alert the user. When this system was first built it alerted us that it used too many flash memory writes, so even thought it was returning 100% valid data, it let us know there was nonetheless an emerging problem. One day I realized that if I could keep a piece of electronics healthy, I could apply the same methodology to humans. For example, I could design a diagnostic toilet that could monitor human health by measuring the levels of biomarkers in urine. The problem was I had no background in biology, so I came back to school to learn about biosensors.

In my business, I was used to world where I provided engineers with solutions, and in return they provided me contracts. The educational community was very different, with low budgets and strict guidelines, and teachers often didn’t have the time or money required for creative problem solving. I reached my goal of bringing creative problem solving into the classroom, but lost my business focus in the process, which ultimately caused me to close my business. But in one of my last business projects, the US Navy contacted me needing a very high reliability system. It was to be launched remotely under the ocean. I came up with a method for predicting a failure in the system before the failure actually occurred. In this technique, which I called gray scaling, the system tests and records system parameters every time the system is turned on. Over time the system learned what was normal, and if the system saw a shift out of normal behavior, it would alert the user. When this system was first built it alerted us that it used too many flash memory writes, so even thought it was returning 100% valid data, it let us know there was nonetheless an emerging problem. One day I realized that if I could keep a piece of electronics healthy, I could apply the same methodology to humans. For example, I could design a diagnostic toilet that could monitor human health by measuring the levels of biomarkers in urine. The problem was I had no background in biology, so I came back to school to learn about biosensors.

I entered the graduate program in Bioengineering at the University California, Riverside, and found bioengineering and microfluidics fascinating. As I looked at biosensors, my background as a system designer made me curious about the components that support biosensors and bioengineering. What I found astonished me. As large a field as bioengineering is, it still does not have a tool set to work from. It does not have the equivalent of a schematic to use in designing, as we do with electronics. So I began developing what I call the MEC system (Multifluidic Evolutionary Components). The system would be a toolkit of components that could allow a systematic construction of a biomedical instrument from a MEC schematic. It became a natural extension of the Snap Circuit System I had previously developed in electronics, but included many fluidic components and their symbolic representations.

The development of the MEC system really moved forward after I joined Dr. Grover’s lab. I began bringing in undergraduate interns from all areas of engineering to help with the development of the MEC system. Dr. Grover’s lab started to overflow with undergraduates designing and coding a toolkit of 3D components, so we secured additional space in Pierce Hall at UCR. I called the new space the “Technology Evolutionary Components Center” or TEC Center. With the new space I could handle more interns, so we advertised the TEC Center to Bourns College of Engineering undergrads at UCR in search of recruiting around five new undergraduates to assist in developing and using the MEC system. When over 50 undergraduates showed up wanting to help, I was excited and maybe a little overwhelmed. The room was packed, and they were all eager to help. There is always more demand for internship opportunities than there is supply, so I hoped that the TEC Center could fill this gap and provide internship opportunities for UCR students. Many of these students are recent arrivals at UCR and have little or no technical experience, but they needed to learn certain tools (SolidWorks, Python, microcontrollers, circuit board design, 3D printing, power tool use, and so on) before they could work in the Center. So I put a special program within the TEC Center called Outreach, in which students work in teams to develop a “Rube Goldberg”-type marble machine. In building this machine, the students develop valuable skills in a wide variety of industry-standard tools. Students are organized into teams according to their background and interests; they can focus on learning skills in their own discipline, or cross over into other fields to learn new skills. Students possessing certain skills are paired with others who are learning these skills.

One of the challenges of running the TEC Center is balancing between teaching, development, and making real progress on real-world problems. What components have we added to the MEC System that will help make that machine that will change lives? To that end, we are discussing with Noah Hass (one of the founders of Floating Doctors how the MEC System might be used in the communities served by Floating Doctors in Panama. I hope to be working on developing real-world solutions to the problems faced in resource-limited communities as the program moves forward.